![<subject>[background image] image of robotics lab (for a robotics and automation)</subject>](images/HP-B.jpg)

Founded in Silicon Valley, California, Areesys is in the business to provide pilot and volume production equipment solutions for PVD (Physical Vapor Deposition) in pan semiconductor. .

Our products and solutions are critical to customers who are at forefronts such as next generation new energy, displays, and advanced packaging (wafer-level, panel-level), as well as processes involving large-sized substrates.

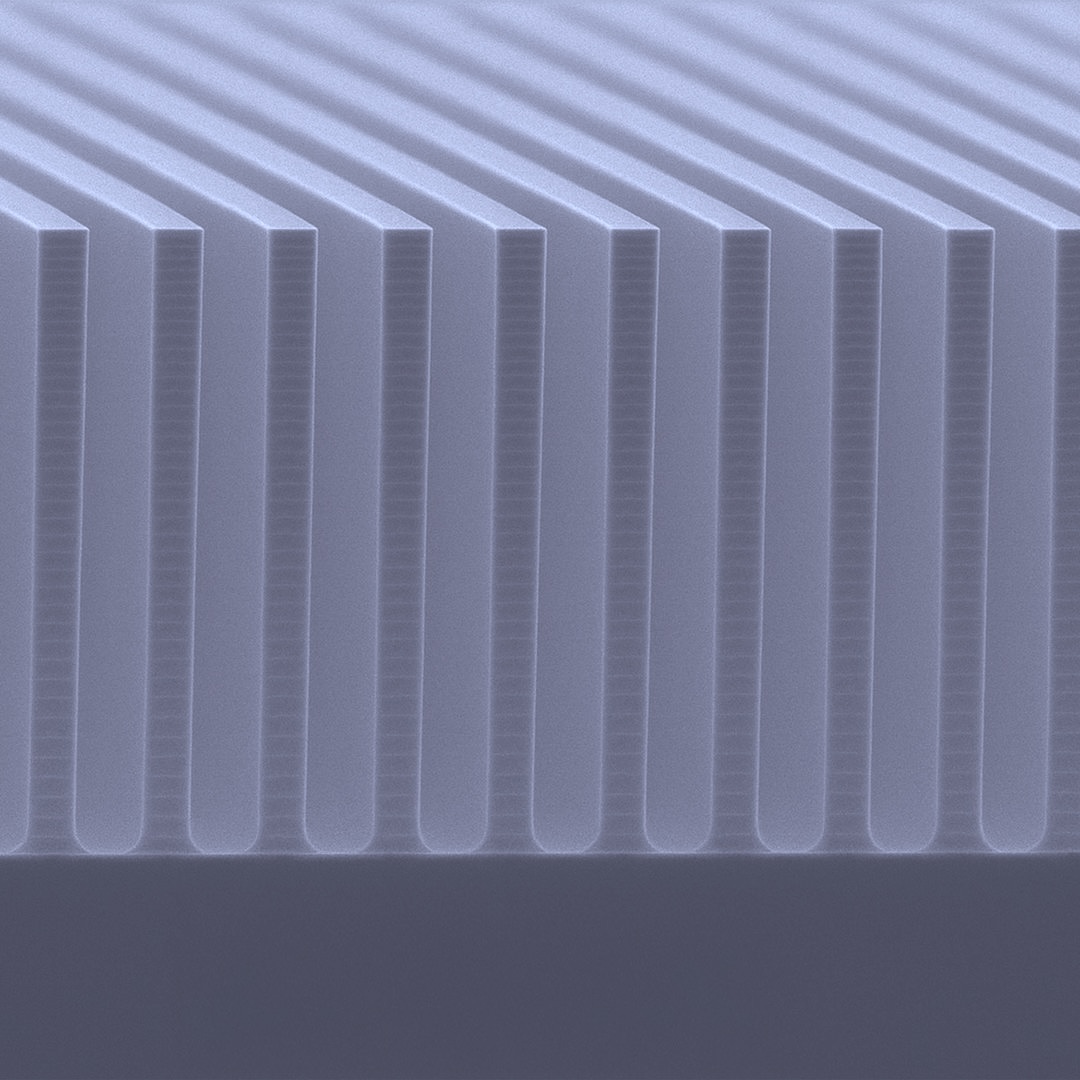

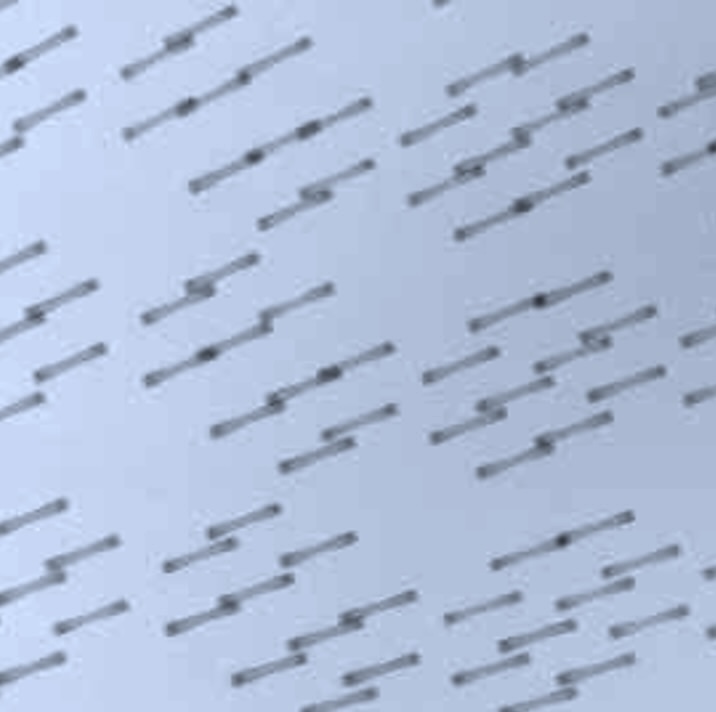

Our core strength lies in offering the high throughput wafer-or panel-level packaging such as Plasma-Enhanced PVD and for high aspect ratio TGV (Through Glass Via) application.

PVD is used in the manufacturing processes which require thin films for optical, mechanical, electrical, acoustic or chemical functions. PVD deposition processes are used to create ultra-thin, ultra-pure metals, metal oxides and transition-metal nitride films for a variety of logic and memory applications in semiconductor manufacturing.

Learn More

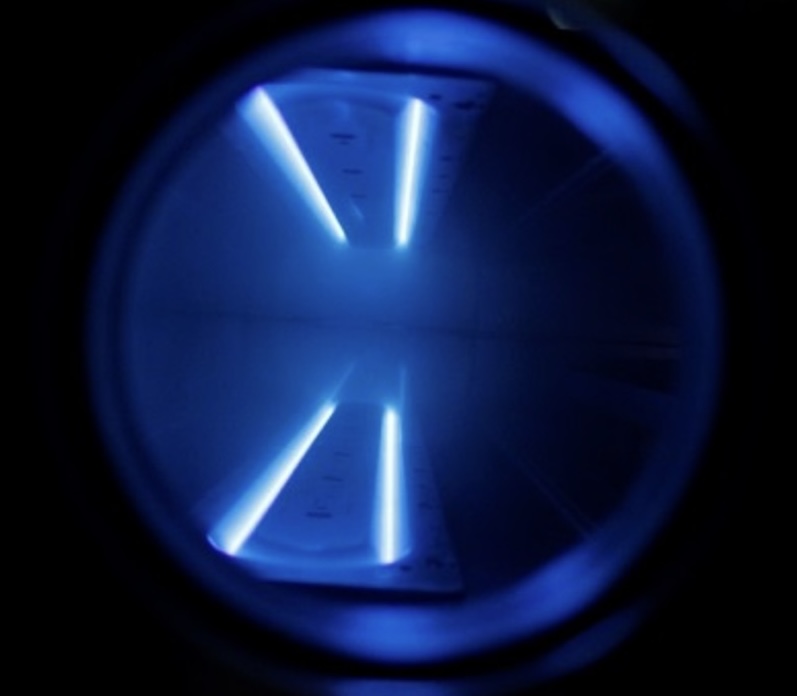

![[background image] image of an academic setting](images/High-Density-Plasma-Source.jpg)

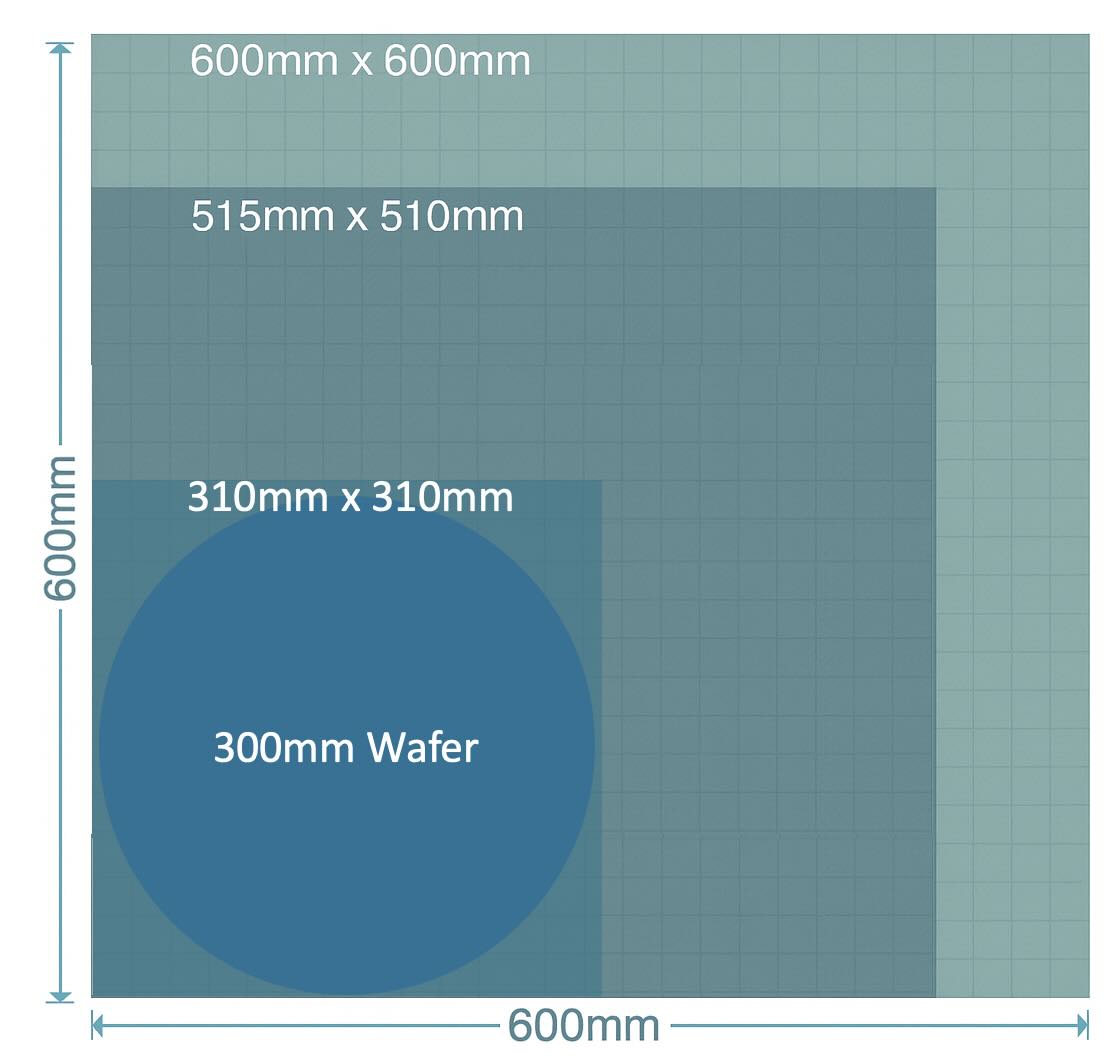

Substrate: 510x515mm; sputter deposition system for large-size TGV (Through Glass Via) substrates, high deposition rate; Large-size planar PVD target with target utilization ≥50%; highly-ionized target materials, high step coverage capability; double-sided sputter deposition with a vacuum flipper

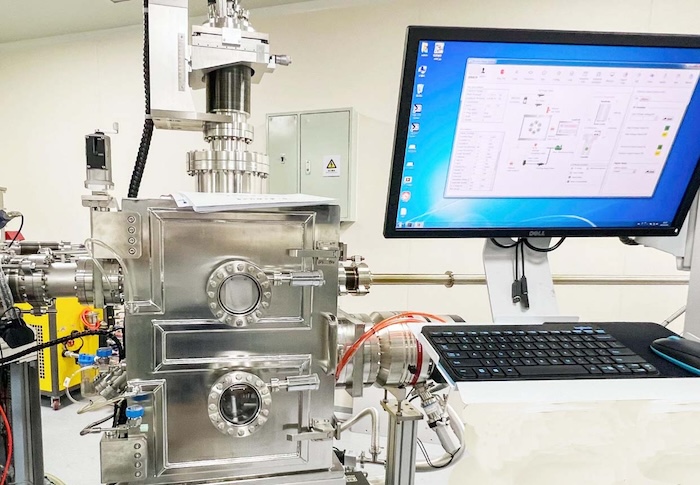

Substrate: 2"~8”; resistive/radiative heating (inert gas and oxygen compatible); integrated resistive heating and liquid nitrogen cooling on the sample stage; fully automated coating process control; sample stage with rotation, lift, translation, and tilt; loading chamber/glove box, compatible with PLD/magnetron sputtering vacuum

High-performance PLD/LMBE; modular design, up to 5-dimensional sample holder, software-enabled automated control, and safety interlock. For substrates up to 8 inches; laser linear scanning for improved film uniformity; the laser window is equipped with a gate valve and a venting gas line, which can be cleaned/replaced without destroying the vacuum state of the main chamber

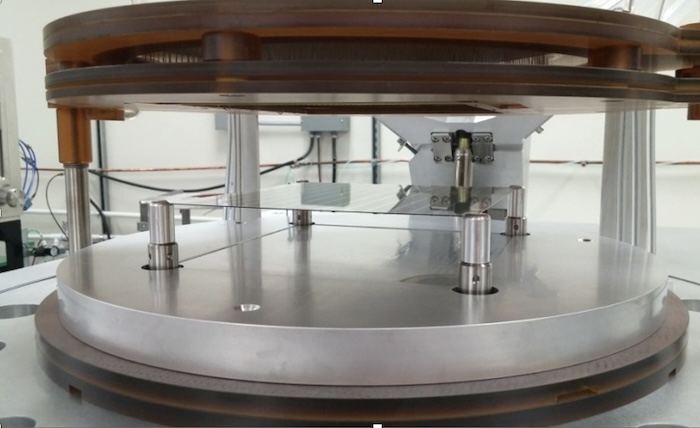

Low-temperature deposition of aluminum thin films for back electrodes on 165mm photovoltaic cell substrates. Process temperature < 140°C (1 micron aluminum). Can be applied for fingerprint sensors and other flexible electronics

Used to polarize PVFD-based polymer films on 210x195mm glass TFT substrates, forming piezoelectric films, a key process in fingerprint chip production

Roll-to-Roll PVD systems for perovskite photovoltaics (PV) is a continuous, high-volume production of thin-film solar cells on flexible substrates using PVD techniques. Affordable and scalable by enabling high-throughput, automated manufacturing processes

Since 2012, the Silicon Valley based Areesys is in the business to develop advanced manufacturing technologies for the global markets in pan semiconductor, electronics, sensor, flat panel display, renewable energy and energy storage.

Our diversified talents come from a broad industry background. It covers new materials discovery, semiconductor, optoelectronics, energy storage, defense systems, and factory automation. It is our invaluable people who have shaped Areesys’s competitive edge to answer the challenges presented by our customers. As a forward-looking team, we have the right expertise and courage to help our customers, in response to their ever changing needs today and tomorrow.

Let our PVD experts help your company grow

We look forward to hearing from you

Kai-an.wang@areesys.com1082 West Hill Court

Cupertino, CA 95014, USA

2F-3, No.99, Jingke S. Rd. Nantun Dist.,

Taichung Citiy 408018, Taiwan